Home About Us Core Strength News Products Case Services Contact Us

Publisher:Kagem Number of visits:417

As a successful person in the twentieth century, both men and women pay special attention to their externalities. The most common is that girls are afraid of lipstick and cups. On the contrary, will the ink on the cup stick to their mouth and is it safe?

As an indispensable element of coloring matter and printing, ink plays an important role in the food packaging printing industry. However, ink poses a safety hazard to the penetration and migration of food packaging. For example, we always like to squeeze the ketchup on the plate, but forget whether the ink above is safe.

In daily life, some people used to use newspapers to lay their desks when eating, completely ignoring the warning that “this plate is a general print, please do not place the food directly on the plate paper”. Some people use old paper to wrap vegetables, raw meat and other foods. These common practices lead to serious food safety hazards.

Because the ink contains a variety of toxic and hazardous substances, if it is in direct contact with food, there is a high possibility of migration.

Foods that are in direct contact with food inks can cause a variety of diseases including cancer.

In China, there is no specific industry standard for inks used in food contact materials. Currently, according to the mandatory national standard “Hygienic Standards for the Use of Additives for Food Containers and Packaging Materials” implemented on June 1, 2009, reference is made to the recommended national standards. Environmental labeling technology requires offset inks, "Environmental marking technology requires gravure inks and flexo inks", and the definition standards for food contact inks are:

1. Do not cause any health hazard to the human body;

2. Under the expected effect, the amount used in food should be reduced as much as possible;

3. It requires the residue and use of heavy metals, volatile organic compounds, benzene solvents, etc. in the ink.

Printing Ink for Food Contact Materials (FCM) refers to any ink applied to materials in contact with food; including direct food contact inks and indirect food contact inks. Instant food contact is a special type of DFC.

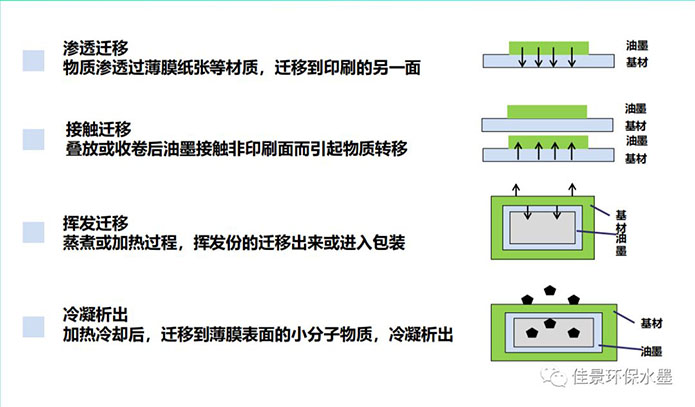

Ink migration is caused by the penetration of pigments in the ink through or through the film to another type of material (sometimes also sticking to the goods in the package). The reason is that the packaging printing ink and the substrate (such as plastic film) contain an excessive amount of plasticizer. Excessive additives in the ink system sometimes cause a part of the ink pigment due to the solvent in the printing ink to cause the substrate (such as In the film), when the stored package print is used in the summer, the printed ink film is softened due to the temperature rise, and the migration speed is accelerated.

On July 13, 2017, the European Commission's Department of Health and Food Safety (DG SANTE) proposed two possible control routes for food contact printing inks:

1. Control measures are based on traditional methods of positive lists;

2. Designate a number of laboratories or consulting agencies to transfer responsibility for regulatory compliance to these designated agencies. These designated agencies need to identify migration materials in food contact materials, conduct migration tests and toxicological tests, then assess their risks and recommend management recommendations.

1. Selection and control of raw and auxiliary materials;

2. Production process control;

3. Printing hygiene requirements;

4. Handling, storage, packaging, storage and transportation;

5. Labels and identification information of inks in direct contact with food;

6. List of raw materials used for food contact inks.

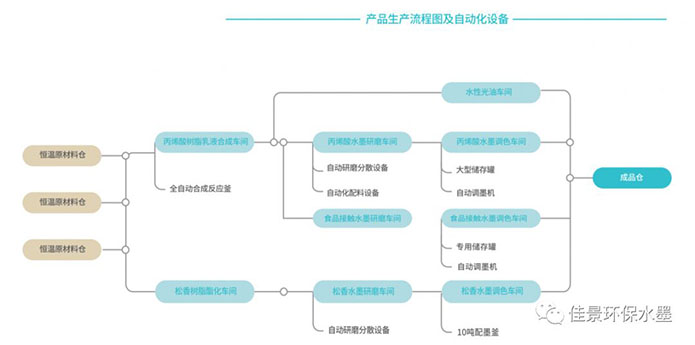

Jiajing has an independent food contact ink grinding workshop and coloring workshop. The food can be in contact with the ink production process in strict accordance with the Production Quality Management Standards (GMP), and the raw materials that can be in direct contact with the food have special marks.

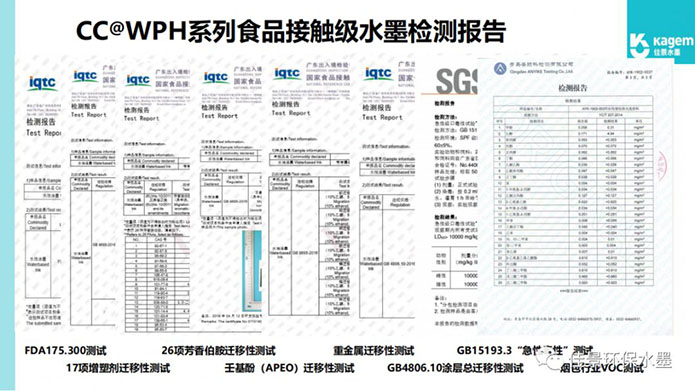

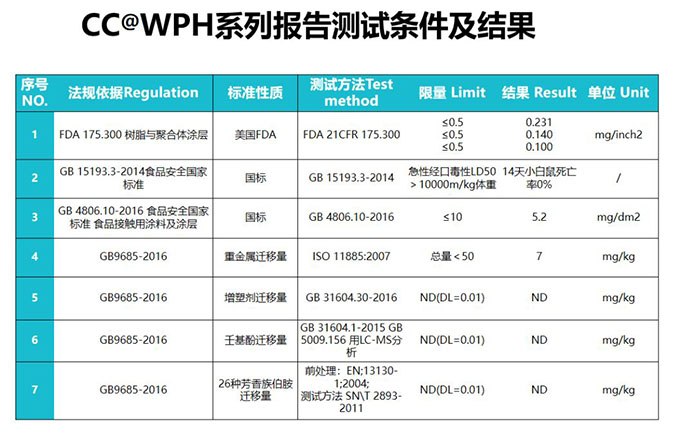

Jiajing Food Contact Ink has passed FDA175.300 test, 17 plasticizer migration test, 26 aromatic primary amine migration test, nonylphenol (APEO) migration test, heavy metal migration test, GB4806.10 coating total Mobility test, GB15193.3 “acute toxicity” test, VOC test in cigarette package industry.

◉ Q1: Where is the food contact ink produced by Jiajing?

Single PE/double PE laminating cup, paper straw, paper bag, paper towel, paper plate, vest bag (KFC, US group takeaway, Carrefour, Baiguoyuan, etc.), self-adhesive label (soy sauce, printed label), wine box, smoke Box and so on.

◉ Q2: What are the characteristics of Jiajing food contact ink?

The product has high color density, bright color, environmental protection, low odor, good film formation and strong adhesion. It is resistant to migration of solvents such as ethanol, acetic acid, n-hexane and potassium permanganate, and meets the food contact materials specified by the state. Related standards. Developed specifically for food, medicine, tobacco and alcohol packaging and printing products.

◉ Q3: What kind of substrate is the food contact ink used on?

Single PE/double PE coating cup, HDPE plastic film, paper towel, cardboard, coated paper

◉ Q4: What are the advantages of Jiajing's production of food contact ink?

Jiajing has been committed to providing “Compliance and Safety” ink products for the industry for 20 years. We have obtained the Green Original and Auxiliary Materials Certification of China Printing Technology Association, and always adhere to the principle of “Consumer Safety First” and comply with relevant regulations and standards and related requirements. Strict adherence. At the same time, our production process ensures that the final product does not endanger human health, does not cause changes in food characteristics, and takes measures to identify, prevent and eliminate the risk of contamination from foreign objects and prevent cross-contamination.

▶ For samples or to learn more about Jiajing Food Contact Ink Products, please contact us.

Guangdong Jiajing Technology Co., Ltd. (hereinafter referred to as Kagem), founded in 1999, specializes in the R&D, production and sales of water-based inks, water-based varnishes, water-based acrylic resins, water-based acrylic emulsions, pearlescent binders and other eco-friendly water-based printing materials.

Add: Shibu Industrial Zone, Liaobu Town,Dongguan, Guangdong 523000 CHINA

Main Line:0086-769-82318231

Fax:0086-769-82318555

Sales:0086-769-82318668

Fax:0086-769-82311109

E-mail:sales@kagem.net